Due to their structural strength and minimal material utilization, hyperboloid cooling towers, sometimes wrongly referred to as hyperbolic cooling towers, have evolved into the design standard for all natural-draft cooling towers. In addition, the hyperbolic shape accelerates the upward convective airflow, increasing cooling effectiveness. Read More…

Our circular FRP (fiberglass reinforced polyester) cooling towers are second to none. With five different models in production- one to meet every need for businesses of all sizes. We are the oldest, full-service fiberglass water cooling tower manufacturer in business today. We bring only the highest quality of customer service to our valued clients. When it comes to FRP cooling towers we bring...

At Delta Cooling Towers, Inc., we specialize in providing high-performance cooling solutions for a wide range of industries. Our innovative cooling towers are engineered to deliver optimal efficiency, durability, and reliability, ensuring that our clients experience effective temperature regulation in their operations.

At SPX Cooling Technologies, we specialize in providing innovative solutions for heat transfer needs through our wide range of high-performance cooling towers. We design, manufacture, and deliver custom-engineered systems that are built to meet the unique requirements of various industrial and commercial applications.

At Cold Shot Chillers, we create a number of chilling systems, including cooling towers. Our products are designed for durability and cost effectiveness. Our engineers can easily custom build any machine to fit the needs of a particular application.

More Hyperbolic Cooling Tower Manufacturers

When most people visualize massive cooling towers, they often associate these structures with nuclear power plants. However, this is a common misconception. In reality, hyperbolic cooling towers are broadly utilized in a wide range of industrial facilities, including large-scale coal-fired power plants, petrochemical refineries, steel manufacturing plants, and more. These iconic hyperboloid-shaped towers are not exclusive to nuclear energy and, in fact, are employed wherever there is a need for highly efficient heat rejection and thermal management of process water or fluids at industrial scale. Furthermore, not all nuclear power plants use hyperbolic cooling towers; some leverage nearby water bodies—such as lakes, rivers, or ocean water—for direct heat exchange. This diversity in cooling tower applications underscores their versatility and vital role in modern industrial infrastructure.

Advanced hybrid cooling tower designs have demonstrated exceptional thermal efficiency, achieving rates of up to 92%. In these configurations, natural draft mechanisms are often combined with mechanical assistance to maximize performance, minimize operational costs, and support environmental sustainability goals through reduced energy consumption.

One of the distinguishing features of true hyperbolic cooling towers is their use of natural draft. By leveraging the principles of fluid dynamics, these towers draw in air naturally—without the need for electrically powered fans—as the warm, buoyant air rises and cooler air is drawn in from the base. This contrasts with mechanical draft cooling tower systems, which often utilize large fans or blowers to force air circulation and are sometimes constructed to mimic the hyperboloid shape for structural or aesthetic reasons. Despite often requiring a significant initial investment due to their large scale and engineering complexity, hyperbolic cooling towers are recognized as some of the most cost-effective and energy-efficient solutions for long-term industrial cooling needs.

How Hyperbolic Cooling Towers Work

The signature hyperboloid shape of these towers is not just for visual impact—it is a marvel of structural engineering and thermodynamic efficiency. The design preserves structural integrity while minimizing the use of construction materials, making it both economical and environmentally conscious. By eliminating the need for mechanical fans typical of forced draft or induced draft cooling towers, hyperbolic towers reduce operational costs and maintenance requirements, making them a preferred choice for industrial-scale cooling in power generation, chemical processing, oil and gas, and metallurgical industries.

Wondering how these massive towers operate without fans? The answer lies in the science of natural convection. The hyperboloid geometry—with its inward curve at the waist and outward flare at the top and bottom—accelerates air movement through the tower by creating a pressure differential. As hot water or process fluid is distributed at the top of the tower, it is broken into small droplets, maximizing the surface area exposed to the updraft of cooler outside air. As the water descends, evaporation occurs, and heat is transferred from the water to the air, effectively cooling the liquid before it is collected at the base for recirculation.

Engineers typically construct the supporting lattice of these towers using stainless steel beams for durability and resistance to corrosion, while the shell is often poured from concrete to withstand the immense structural loads and environmental stresses. The inherent strength of the hyperboloid shape allows these towers to withstand severe weather, high winds, and even seismic activity, making them ideal for regions with challenging environmental conditions.

Natural draft cooling towers operate on a simple yet effective principle: hot water or process fluid is pumped to the top of the tower and distributed over fill media, which increases the contact area between the water and the upward moving air. As gravity pulls the water downward, heat is transferred to the air through evaporation, and the cooled water is collected at the bottom for reuse. This self-sustaining air flow eliminates the need for powered fans, contributing to lower operational costs and enhanced reliability. Interested in how natural draft towers compare to mechanical draft options? Explore more about cooling tower designs here.

Despite their robust construction and use of high-quality materials, hyperbolic cooling towers are susceptible to corrosion and biofouling due to fluctuating wet and dry conditions within the structure. Effective maintenance routines, corrosion-resistant coatings, and advanced water treatment systems are essential to ensure optimal performance and longevity.

Key Applications of Hyperbolic Cooling Towers

Hyperbolic cooling towers play a pivotal role in a diverse array of industrial processes that require large-scale heat rejection. Some of the most common and high-impact applications include:

- Power Generation: Hyperbolic cooling towers are integral to both nuclear power plants and thermal power stations (coal, gas, oil) for dissipating waste heat generated during electricity production. Their ability to efficiently cool large volumes of circulating water makes them indispensable in maintaining safe operating temperatures and maximizing plant efficiency.

- Petrochemical and Chemical Processing: Chemical plants and refineries use hyperbolic cooling towers to manage process heat and stabilize critical temperatures in reactors, condensers, and exchangers. This enhances product quality, worker safety, and equipment longevity.

- Steel and Metallurgical Industries: Hyperbolic cooling towers are relied upon to cool process water, blast furnaces, and heat exchangers, ensuring consistent product quality and reducing the risk of equipment failure due to overheating.

- District Cooling and HVAC: In urban environments and large commercial complexes, hyperbolic cooling towers are utilized for district cooling systems, greatly improving energy efficiency and reducing the environmental impact of air conditioning for entire neighborhoods or business districts.

- Industrial Process Water Recycling: Facilities looking to conserve water and minimize environmental footprint use cooling towers to recycle process water, significantly lowering freshwater demand and wastewater discharge.

Comprehensive Benefits of Hyperbolic Cooling Towers

- Energy Efficiency and Cost Savings: By leveraging natural draft, these towers minimize the need for electrically powered fans, which translates to lower energy consumption and operational costs over the lifecycle of the facility.

- High Capacity and Scalability: Hyperbolic cooling towers can handle extremely large volumes of water, making them ideal for high-capacity industrial plants and future expansion needs.

- Structural Durability: The unique shape distributes mechanical stress evenly, providing excellent resistance to wind loads, natural disasters, and long-term wear.

- Reduced Environmental Impact: Natural draft operation reduces greenhouse gas emissions and reliance on grid electricity, aligning with corporate sustainability and regulatory compliance goals.

- Low Maintenance: Fewer moving parts mean reduced maintenance requirements, longer service life, and increased system uptime. When integrated with advanced water treatment and filtration systems, hyperbolic towers deliver consistent, reliable performance.

- Water Conservation: By recirculating process water, industrial facilities can reduce freshwater usage, an increasingly important consideration as water scarcity becomes a global concern.

- Enhanced Process Control: Stable and predictable cooling allows for tighter control over process variables, improving product quality and operational reliability.

Comparing Hyperbolic Cooling Towers to Other Cooling Tower Types

Are you considering the right cooling tower for your facility? Understanding the differences between hyperbolic cooling towers and other types—such as mechanical draft, crossflow, counterflow, and hybrid systems—can help guide your decision.

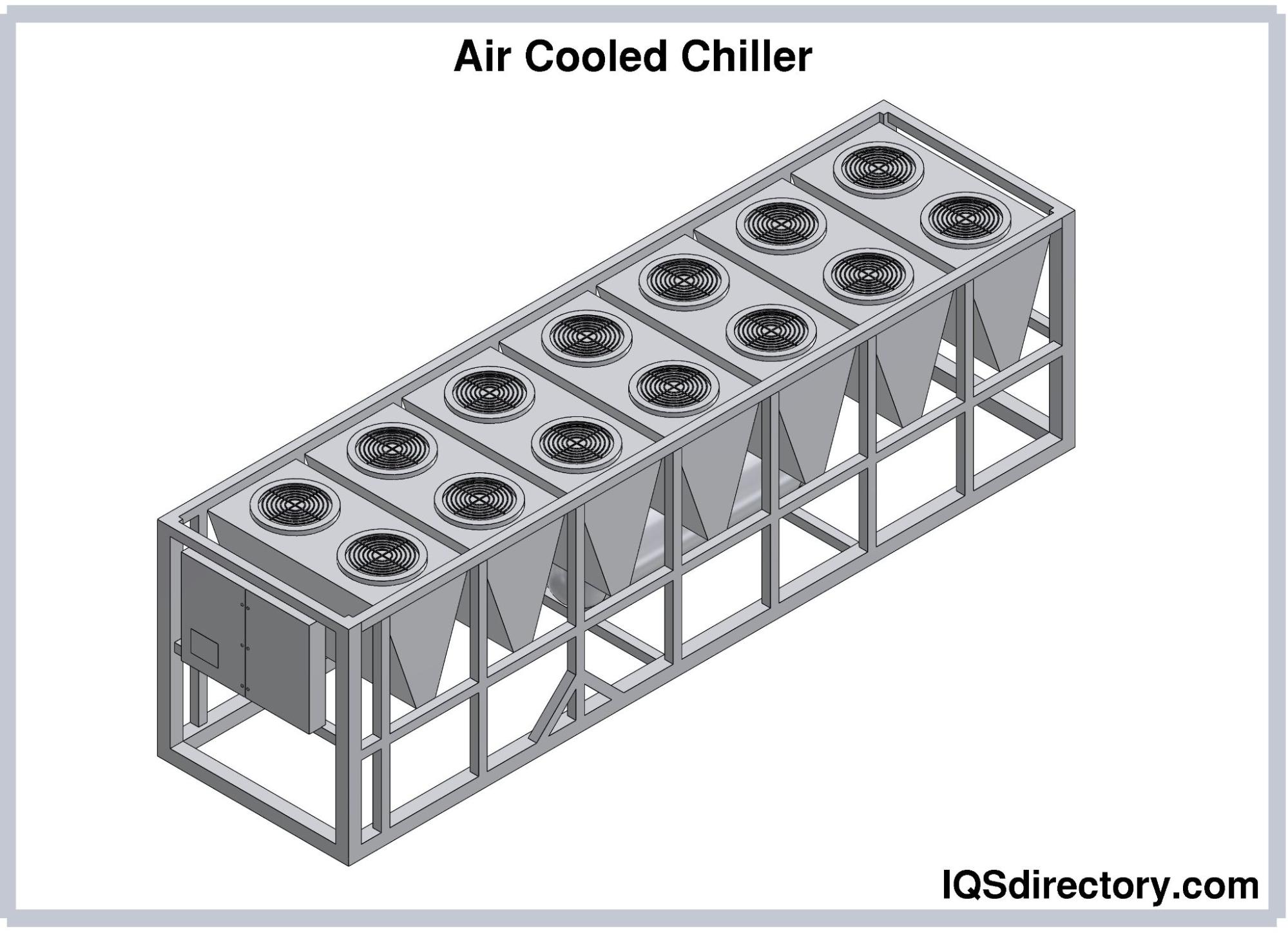

- Mechanical Draft Cooling Towers: Use large fans to force or induce air movement. They are more compact and suitable for smaller or space-constrained installations but require higher energy input and maintenance for fan operation.

- Crossflow and Counterflow Towers: Vary in how water and air move relative to each other. While efficient for moderate loads, they may not offer the same scalability or energy savings as hyperbolic designs for large-scale applications.

- Hybrid Cooling Towers: Combine natural and mechanical draft principles to balance thermal efficiency and water conservation while reducing visible plume formation. These are increasingly popular in areas with strict environmental regulations.

For an in-depth guide, see Cooling Tower Design: Types, Selection & Applications.

Key Factors When Selecting a Hyperbolic Cooling Tower Supplier

Choosing the right supplier or manufacturer is crucial for the success of your industrial cooling project. Here are some important decision factors to consider:

- Experience and Reputation: Look for suppliers with a proven track record in designing, manufacturing, and installing hyperbolic cooling towers for similar industries and facility sizes.

- Engineering Capabilities: Top suppliers offer custom solutions tailored to your site conditions, process requirements, and regulatory environment. This includes expertise in thermal performance modeling, structural engineering, and environmental compliance.

- Material Quality: Ensure that all components, from stainless steel beams to concrete shells and fill media, meet relevant standards for corrosion resistance, strength, and longevity.

- After-Sales Support: Reliable suppliers provide comprehensive technical support, maintenance services, spare parts availability, and prompt response to operational issues.

- Environmental and Safety Standards: Confirm that the supplier adheres to local and international safety, emissions, and water usage regulations, such as ISO 9001 and 14001 certifications.

- Total Cost of Ownership: Evaluate not just the initial investment, but also long-term operating costs, maintenance requirements, and potential energy savings.

Ready to compare leading hyperbolic cooling tower manufacturers? Use our Hyperbolic Cooling Towers Supplier Directory to review company profiles, capabilities, and customer reviews. You can also request quotes from multiple suppliers at once to find the best fit for your project.

Optimizing Performance and Maintenance of Hyperbolic Cooling Towers

Maintaining peak performance in hyperbolic cooling towers involves more than just robust design. Here are some best practices for ongoing operation and maintenance:

- Water Quality Management: Unclean water, contaminated with pollen, dirt, bacteria, and organic material, can lead to scaling, biofilm formation, and the proliferation of waterborne pathogens like Legionella. This buildup can clog nozzles, reduce heat transfer efficiency, and increase energy usage. Implementing advanced filtration and water treatment solutions is essential for system longevity and safety.

- Regular Inspections: Conduct scheduled structural and mechanical assessments to identify early signs of corrosion, cracking, or wear. Proactive maintenance helps avoid costly downtime and repairs.

- Sludge and Debris Removal: Minimize sludge accumulation in basins and channels to maintain optimal water flow and heat exchange. Modern filtration systems and automated cleaning technologies can reduce manual intervention.

- Monitoring and Automation: Utilize sensors and automated controls to monitor water temperature, flow rates, and air movement in real time. This data-driven approach allows for rapid adjustments, improved efficiency, and early detection of anomalies.

- Staff Training: Ensure that operational teams are trained in the specific requirements of hyperbolic cooling tower management, including safety protocols, maintenance routines, and emergency response.

Frequently Asked Questions About Hyperbolic Cooling Towers

- What industries benefit most from hyperbolic cooling towers?

Industries with high heat rejection needs—such as power generation, petrochemicals, steel manufacturing, and large-scale HVAC—derive the greatest benefit from the scalability and efficiency of hyperbolic cooling towers. - How do hyperbolic cooling towers contribute to sustainability?

By using natural draft and supporting water recycling, these towers significantly reduce energy consumption, minimize freshwater withdrawal, and support emissions reduction initiatives. - What are the main maintenance challenges?

Addressing water quality, preventing corrosion, and controlling biofouling are the primary challenges. Integrating modern filtration, automated monitoring, and corrosion-resistant materials is critical for overcoming these issues. - How do I determine the right cooling tower size for my facility?

Sizing depends on factors like process heat load, climate, available space, and local regulations. Leading suppliers can provide customized thermal modeling and capacity planning services. - What is the typical lifespan of a hyperbolic cooling tower?

With proper maintenance and quality materials, these structures can serve reliably for 30–50 years or longer.

Still have questions? Contact our cooling tower experts for personalized guidance or to request a site evaluation.

Next Steps: Selecting and Sourcing Hyperbolic Cooling Towers

Securing the right hyperbolic cooling tower for your facility is a critical decision that impacts safety, efficiency, and operational costs for decades to come. Here’s a step-by-step approach to ensure a successful purchase and implementation:

- Assess Your Needs: Define your cooling requirements, site constraints, and sustainability objectives. Calculate your process heat load and desired water temperature range.

- Research Technologies: Compare hyperbolic towers to other types (mechanical, hybrid, crossflow, counterflow) for fit with your operational profile.

- Shortlist Suppliers: Use directories and industry reviews to identify reputable manufacturers with relevant experience and positive references.

- Request Proposals: Solicit detailed quotes, including engineering studies, projected energy savings, and maintenance schedules.

- Evaluate Total Cost of Ownership: Consider upfront investment, energy and water savings, maintenance costs, and expected service life.

- Visit Reference Sites: Whenever possible, tour existing installations to see the towers in operation and gather user feedback.

- Finalize Design and Place Order: Work closely with your chosen supplier for optimal customization and a seamless installation process.

Ready to get started? Request quotes from top hyperbolic cooling tower manufacturers now and take the next step toward reliable, energy-efficient industrial cooling.

By understanding the unique advantages, applications, and design considerations of hyperbolic cooling towers, facility managers and engineers can make informed decisions to optimize industrial cooling performance, reduce costs, and support environmental stewardship. Whether you’re upgrading an existing system or planning a new installation, exploring all your options and working with trusted suppliers is the key to long-term success. Connect with our team today for expert advice and customized solutions tailored to your project needs.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services