Chillers cooling towers are an essential component of modern air conditioning systems and industrial processes. These systems work by removing heat from water or air and transferring it to the surrounding environment. Read More…

Cooling Tower Systems has manufactured various models of cooling tower systems and related equipment for over 40 years, with five different models in production- one to meet every need for businesses of all sizes. We are the oldest, full-service fiberglass water cooling tower manufacturer in business today. All CTS cooling towers are designed, engineered and tested by our own factory research and ...

At Delta Cooling Towers, Inc., we specialize in providing high-performance cooling solutions for a wide range of industries. Our innovative cooling towers are engineered to deliver optimal efficiency, durability, and reliability, ensuring that our clients experience effective temperature regulation in their operations.

At SPX Cooling Technologies, we specialize in providing innovative solutions for heat transfer needs through our wide range of high-performance cooling towers. We design, manufacture, and deliver custom-engineered systems that are built to meet the unique requirements of various industrial and commercial applications.

At Cold Shot Chillers, we create a number of chilling systems, including cooling towers. Our products are designed for durability and cost effectiveness. Our engineers can easily custom build any machine to fit the needs of a particular application.

More Chillers Cooling Tower Manufacturers

Components of Chillers Cooling Towers

Chillers cooling towers are engineered systems designed to remove excess heat from buildings or industrial processes, supporting efficient climate control and equipment operation. Understanding the main components of chillers cooling towers is crucial for facility managers, engineers, and procurement professionals seeking reliable cooling solutions. Typical components include:

- Condenser Coils: These facilitate heat rejection by transferring absorbed heat from the refrigerant to the air or cooling water. High-performance condenser coils are essential for maximizing energy efficiency and ensuring optimal thermal exchange.

- Evaporator Coils: Responsible for absorbing heat from process water or air, evaporator coils are critical for lowering temperatures within the chilled water loop.

- Compressors: Acting as the engine of the chiller, compressors increase refrigerant pressure and keep the cooling cycle moving. Scroll, screw, centrifugal, and reciprocating compressors are commonly found in industrial chillers.

- Water Pumps: Pumps circulate water between chillers, cooling towers, and process equipment, ensuring consistent flow rates and system performance.

- Fans: High-efficiency fans draw or force airflow across condenser coils or fill media, facilitating rapid heat removal from the system.

- Water Treatment Systems: These systems maintain water quality by filtering impurities, balancing pH, and preventing mineral scale, corrosion, and biological growth such as Legionella.

- Control Systems: Modern chillers cooling towers utilize advanced control panels and automation technology to regulate temperature, monitor system health, and optimize energy use. Integration with building management systems (BMS) is increasingly common.

Are you evaluating chillers cooling tower components for a new project or retrofit? Contact leading manufacturers to compare component options, efficiency ratings, and maintenance requirements tailored to your specific industry needs.

Variations of Chillers Cooling Towers

Chillers cooling towers are not one-size-fits-all. Their configurations and technologies vary to suit different operational demands, climate conditions, and space constraints. Selecting the right type of chiller cooling tower can have a profound impact on system performance, cost, and reliability. Key variations include:

- Open Circuit Cooling Towers: These systems expose process water directly to the air, which maximizes heat transfer but can increase risk of contamination and evaporation losses. Commonly used in heavy industry and large-scale HVAC applications.

- Closed Circuit Cooling Towers (Fluid Coolers): Here, process fluid circulates inside a closed loop, separated from outside air by a heat exchanger coil. This reduces contamination, water treatment needs, and overall maintenance—making it ideal for data centers, food processing, and mission-critical environments.

- Single Stage Chillers: Utilized in processes where temperature precision is less critical, these chillers offer simplicity and cost-effectiveness for basic HVAC or light industrial cooling.

- Multistage Chillers: For industries requiring fine control over temperature (such as pharmaceuticals or semiconductor manufacturing), multistage chillers provide greater accuracy and operational flexibility.

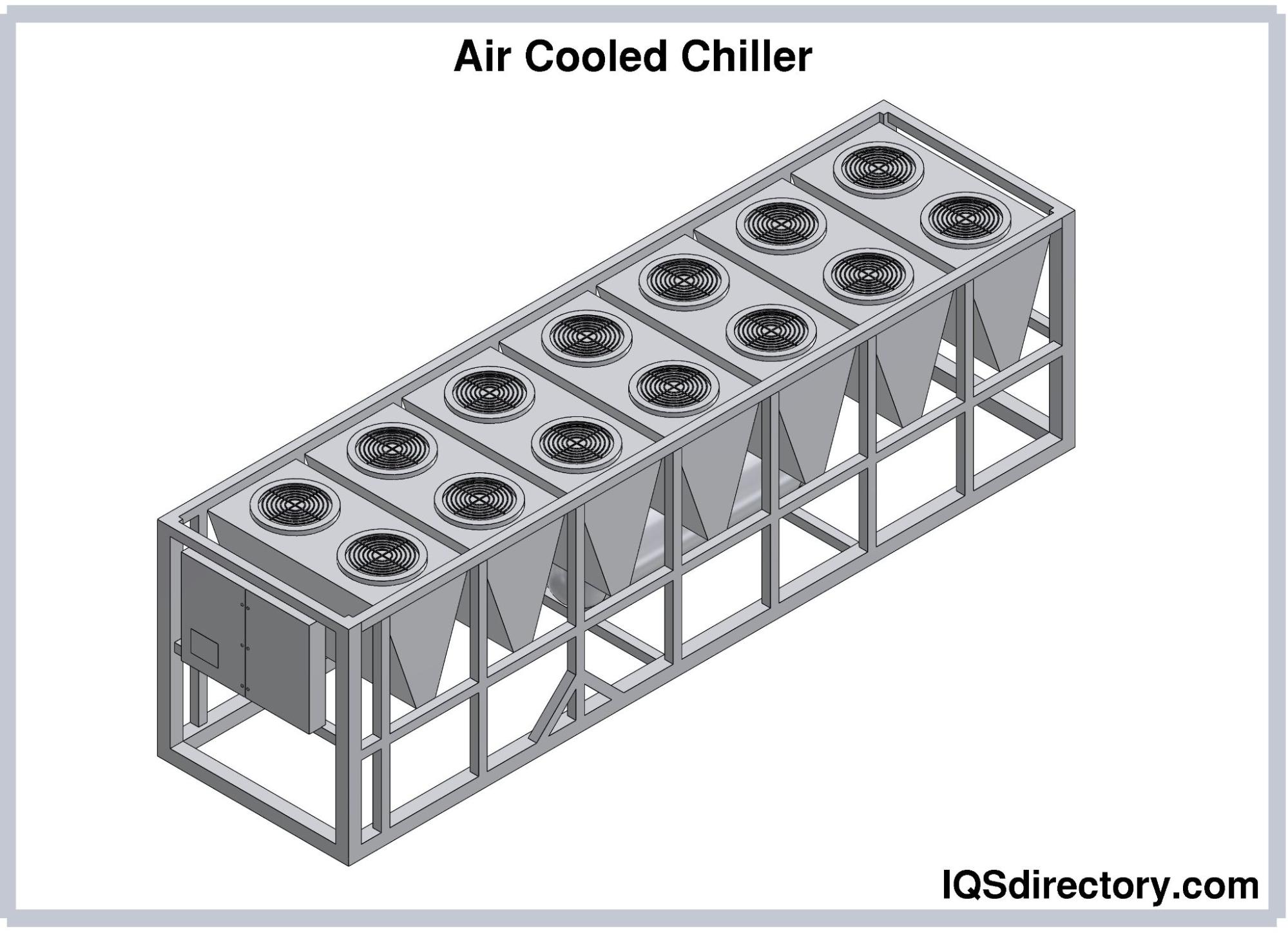

- Air-Cooled Chillers: These chillers use ambient air to reject heat, making them suitable for locations with limited water supply. They are favored for rooftop installations, commercial buildings, and retrofits where water conservation is a priority.

- Water-Cooled Chillers: Leveraging cooling towers and abundant water sources, these systems deliver superior energy efficiency and quieter operation—key for hospitals, high-rise buildings, and large manufacturing plants.

- Absorption Chillers: Utilizing waste heat (steam, hot water, or exhaust gases) instead of electricity-driven compressors, absorption chillers are a sustainable choice for facilities with available heat byproducts and high energy costs.

Not sure which chiller cooling tower variation is right for your facility? Explore our comprehensive buying guide or connect with industry experts to compare system types, analyze lifecycle costs, and identify the best fit for your application.

Considerations Regarding Chillers Cooling Towers

Choosing and operating chillers cooling towers involves several critical considerations that influence performance, cost, and compliance. Addressing these factors ensures long-term reliability, energy efficiency, and safety. Common concerns include:

- Legionella and Waterborne Pathogens: Open-loop systems are susceptible to microbial growth, including Legionella bacteria, which can cause serious health risks. Implementing robust water treatment protocols—such as biocides, filtration, and regular monitoring—mitigates these dangers.

- Noise Pollution: Large fans, pumps, and water flow can generate significant noise. In urban or residential settings, it’s vital to evaluate system acoustics, select low-noise models, and implement sound attenuation measures during installation.

- Installation and Initial Costs: While chillers cooling towers may involve higher upfront investment compared to conventional air-cooled systems, their enhanced energy efficiency, lower operational costs, and longer lifespan often yield better total cost of ownership (TCO) over time.

- Ongoing Maintenance: Regular inspection, cleaning, descaling, and chemical treatments are essential to prevent fouling, corrosion, and system inefficiencies. Many facilities now utilize predictive maintenance tools and IoT sensors to streamline upkeep.

- Energy Consumption: Selecting energy-efficient models, optimizing load management, and leveraging variable frequency drives (VFDs) can significantly reduce electricity usage and operating expenses.

- Space Requirements: Evaluate available real estate for tower placement, access for service, and airflow clearance to ensure proper system performance.

- Environmental Regulations: Increasingly strict local, state, and federal regulations govern water usage, chemical discharge, drift, and noise. Always consult with compliance experts or manufacturers to ensure your installation meets all legal requirements.

Looking to minimize operating costs and environmental impact? Ask our specialists about eco-friendly chillers cooling tower solutions and strategies for regulatory compliance in your sector.

Benefits of Chillers Cooling Towers

Chillers cooling towers offer a host of advantages that make them a preferred choice for commercial, industrial, and institutional cooling applications. Here are some of the most impactful benefits of chillers cooling towers:

- Superior Energy Efficiency: By leveraging evaporative cooling and optimized heat exchange, these systems use less energy than traditional air conditioning units. This translates to lower utility bills and a stronger ROI for owners and operators.

- Longer Equipment Lifespan: Chillers cooling towers are engineered for durability and robust performance, often outlasting comparable cooling technologies. Proper maintenance further extends system longevity.

- Precise Temperature Control: Advanced controls and multistage chillers enable fine-tuned temperature regulation, which is vital for sensitive manufacturing processes or specialized climate control (such as laboratories and cleanrooms).

- Reduced Environmental Impact: By minimizing energy consumption and water waste, these systems help organizations meet sustainability goals and reduce their carbon footprint. Many modern models are compatible with green building standards such as LEED.

- Scalability and Flexibility: Modular designs and customizable options allow chillers cooling towers to adapt to changing cooling demands, facility expansions, or new regulatory requirements.

- Improved Indoor Air Quality: Effective humidity and temperature control supports healthy indoor environments in offices, schools, healthcare facilities, and residential complexes.

- Operational Cost Savings: The combination of energy efficiency, low maintenance requirements, and extended lifespan lowers total lifecycle costs, providing excellent value for long-term investments.

- Reliability in Critical Applications: Chillers cooling towers deliver consistent performance for mission-critical operations—such as data centers, hospitals, and manufacturing plants—where downtime is not an option.

Ready to upgrade your facility’s cooling infrastructure? Request a free consultation to learn how modern chillers cooling towers can maximize energy savings and operational resilience for your business.

Applications of Chillers Cooling Towers

Chillers cooling towers serve as the backbone of climate control and process cooling across a diverse array of industries. Their adaptability and performance make them indispensable for many demanding environments. Key applications for chillers cooling towers include:

- Commercial and Residential Air Conditioning: Large-scale HVAC systems in office buildings, shopping malls, airports, hotels, and apartment complexes rely on chillers cooling towers to provide efficient, cost-effective temperature control and humidity management.

- Industrial Process Cooling: Factories, refineries, and chemical plants use chillers cooling towers to dissipate process heat, safeguard equipment, and ensure product quality in operations such as steel manufacturing, plastics extrusion, and pulp and paper production.

- Data Centers: To prevent overheating and ensure uptime, data centers utilize high-capacity chillers cooling towers for reliable server room cooling and thermal management.

- Pharmaceuticals and Biotechnology: Precise temperature regulation is essential for research labs, vaccine manufacturing, and cleanrooms—making chillers cooling towers vital for compliance and product safety.

- Food and Beverage Processing: From breweries and dairies to cold storage warehouses, these systems maintain strict temperature and humidity levels required for food safety and freshness.

- Healthcare Facilities: Hospitals, medical centers, and laboratories depend on chillers cooling towers to support sensitive equipment (MRI, CT scanners), maintain sterile environments, and ensure patient comfort.

- Power Generation: Power plants use chillers cooling towers to cool turbine condensate and manage thermal loads, which is critical for operational efficiency and emissions control.

- Automotive and Electronics Manufacturing: Consistent cooling is required for precision machining, injection molding, and electronics assembly, where heat can affect tolerances and product reliability.

Curious about the ideal chillers cooling tower application for your facility? Browse real-world case studies or contact our engineering team to discover custom solutions for your unique requirements.

Choosing the Right Chillers Cooling Tower Manufacturer

Selecting a reputable chillers cooling tower manufacturer is crucial to the success of your cooling project. The right partner can provide expert guidance, tailored system design, reliable installation, and long-term support. When evaluating suppliers, consider the following factors:

- Industry Experience: Look for manufacturers with a proven track record in your specific industry—whether it’s commercial HVAC, industrial process cooling, or specialized sectors like healthcare or data centers.

- Product Range and Customization: A diverse product portfolio allows you to select or customize a system that aligns with your facility’s capacity, efficiency, and compliance needs.

- Certifications and Compliance: Ensure the manufacturer meets relevant industry standards (ASHRAE, ISO, UL, CTI certification) and local regulatory requirements for safety, energy efficiency, and environmental impact.

- After-Sales Support and Service: Comprehensive maintenance programs, spare parts availability, and technical support are vital for minimizing downtime and maximizing ROI.

- Innovative Technology: Top manufacturers invest in R&D, offering advanced controls, IoT integration, energy monitoring, and predictive maintenance solutions for smarter, more efficient operation.

- Customer Reviews and References: Research feedback from previous clients, request references, and review case studies to gauge supplier reliability and project success rates.

To ensure you have the most positive outcome when purchasing a chillers cooling tower from a chillers cooling tower manufacturer, it is important to compare several companies using our directory of chillers cooling tower manufacturers. Each chillers cooling tower manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each chillers cooling tower business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple chillers cooling tower companies with the same form.

Searching for the best chillers cooling tower manufacturer for your next project? Start your supplier comparison now to access detailed product data, request custom quotes, or schedule a consultation with industry-leading experts.

Frequently Asked Questions About Chillers Cooling Towers

What is the typical lifespan of a chillers cooling tower system?

With proper maintenance, most chillers cooling towers last 15–25 years, depending on the quality of components, water treatment practices, and operational conditions.

How do I determine the right capacity for my chillers cooling tower?

Capacity requirements depend on process heat load, ambient conditions, and required temperature ranges. Work with a qualified engineer or use online sizing calculators provided by manufacturers to ensure optimal performance and efficiency.

What maintenance is required for optimal performance?

Routine maintenance includes cleaning coils, inspecting fans and pumps, monitoring water chemistry, checking for leaks, and testing control systems. Many facilities now employ predictive analytics and remote monitoring to identify issues before they escalate.

Are there eco-friendly options for chillers cooling towers?

Yes, many manufacturers offer systems that use environmentally friendly refrigerants, minimize water consumption, and incorporate energy-saving features such as variable speed drives and advanced heat exchangers.

How can I reduce noise from my chillers cooling tower installation?

Choose low-noise models, implement acoustic enclosures, and work with manufacturers to design for noise abatement—especially important in residential or urban applications.

Have more questions? Contact our team for expert advice on selecting, installing, and maintaining the most efficient chillers cooling tower systems for your facility.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services